Cable tray mould is the main tool used to make subgrade cable tray. It is simple and convenient to operate and can meet a variety of manufacturing requirements. The quality of products will be affected by the quality of cable tray mould.

在制作前,需要让专业的设计人员对其进行设计,保证制作的产品的形状可以满足施工的要求。制作好的井盖模具图纸交由工厂的加工工人,工人利用数控机床,将整体的钢板进行切割,分为面板和筋板

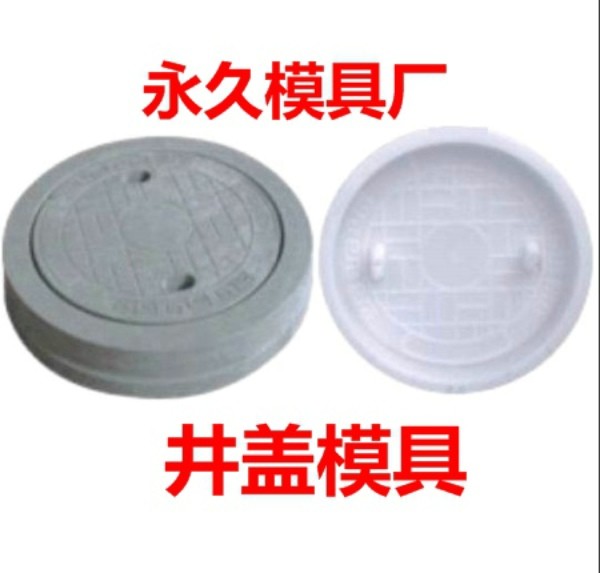

Before production, professional designers need to design it to ensure that the shape of the produced products can meet the construction requirements. The prepared cable tray mold drawing shall be handed over to the processing workers of the factory. The workers use the CNC machine tool to cut the overall steel plate into panel and rib plate

The main function of the panel is to fix the raw materials. In the process of natural air drying, it can maintain a certain shape, so that it can be formed according to the shape of the mold and can be used normally.

筋板的主要作用是焊接在面板上,起到增强模具的抗压能力的作用,在浇灌原料时不会出现变形甚至是损坏,可以保持较好的形状。

The main function of rib plate is to weld on the panel to enhance the compressive capacity of the mold. It will not deform or even damage when pouring raw materials, and can maintain a good shape.

在焊接完成后需要进行内腔打磨,因为只有光滑的内腔才能制作出表面平整的产品,这样会使产品的耐用性有很大的提升。

After welding, the inner cavity needs to be polished, because only a smooth inner cavity can produce a product with flat surface, which will greatly improve the durability of the product.