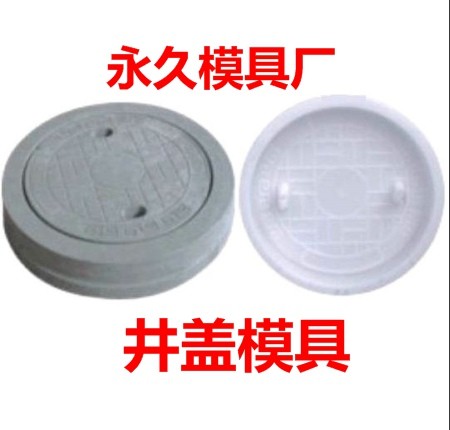

井盖模具的种类根据不同的材质进行分类,主要塑料井盖模具和井盖钢模具,井盖吸塑模片主要用户小区道路.井盖模具的使用已经成为了市政道路建设的最主要的生产工艺

The types of well cover molds are classified according to different materials, mainly plastic well cover molds and well cover steel molds, and well cover blister molds are mainly used in community roads. The use of well cover molds has become the most important production process of municipal road construction

随着城市的不断发展,越来越多的工程建设不断发展,井盖模具呈现供不应求的状态,为了满足市场的需求,井盖模具不断被生产制造

With the continuous development of the city and more and more engineering construction, the well cover mold is in short supply. In order to meet the market demand, the well cover mold is continuously manufactured

井盖模具基本加工过程很简单,将粉末状或液状聚合物放在模具里,加热同时围绕两个垂直轴旋转,然后冷却。

The basic processing of the well cover mould is very simple. The powder or liquid polymer is placed in the mould, heated and rotated around two vertical axes at the same time, and then cooled.

在加热阶段的最初,如果用的是粉末状材料,将模具表面形成多孔层,然后随循环过程渐渐熔融,形成均匀厚度的均相层,如果用的是液体材料,则先流动和涂覆在模具表面,当达到凝胶点时则完全停止流动。

At the beginning of the heating stage, if the powder material is used, the surface of the mold will form a porous layer, and then melt gradually with the circulation process to form a homogeneous thickness homogeneous layer. If the liquid material is used, it will first flow and coat on the mold surface, and when the gel point is reached, it will stop flowing completely.

模具随后转入冷却工区,通过强制通风或喷水冷却,然后被放置于工作区,在这里,模具被打开,完成的制件被取走,接着在进行下一轮循环。

The mold is then transferred to the cooling work area, cooled by forced ventilation or water spray, and then placed in the work area, where the mold is opened, the finished parts are taken away, and then the next cycle is carried out.